Specialising in the Lost Wax Casting Technique

Along with traditional silversmithing skills I specialise in the ancient Lost Wax Casting technique to create tiny, detailed sculptures in precious metals. These micro sculptures are then crafted into jewellery - a Lost Wax Treasure especially for you or a loved one, that will be adored and cherished for generations to come.

What is Lost Wax Casting?

Lost wax casting is an ancient technique for making metal objects—such as jewellery, sculpture, and machine parts—using a wax model of the desired item. The technique gets its name because during the process the wax model is melted away and "lost" leaving a void that can be filled with molten metal. After the metal cools and hardens, it takes the exact shape of the original wax model, capturing even the smallest details. The earliest known examples of lost wax sculptures are over 6000 years old and were discovered in the Indus Valley. The lost wax casting process is still used today for both jewellery and industrial purposes and since its concept thousands of years ago the technique has been enhanced and refined with modern technology and materials.

What are the stages of the Lost Wax Casting Process?

Each of my Lost Wax Treasures starts out as a piece of wax. I hand carve and sculpt the wax using specialist carving and wax modelling tools. This wax sculpture (also referred to as a pattern) is a precise rendering of the final item I want to create. Out of the whole process this part usually takes the most time and creativity with some patterns taking many hours to complete.

When the pattern is finished the technical part of the process begins and it’s time to attach a sprue to the pattern. A sprue is a small wax rod that acts as a channel for the molten metal to flow in during the cast. Several patterns can be attached together with small sprues to form a wax “tree” on a central larger sprue. Care has to be taken to sprue the patterns together to ensure a successful cast,

The tree is then inserted into a rubber base (called a foot) and placed in a casting flask, the flask is filled with a special type of heat-resistant plaster called investment. The investment is placed in a vacuum to remove the air bubbles in the investment and ensure a smooth mixture to set around the patterns.

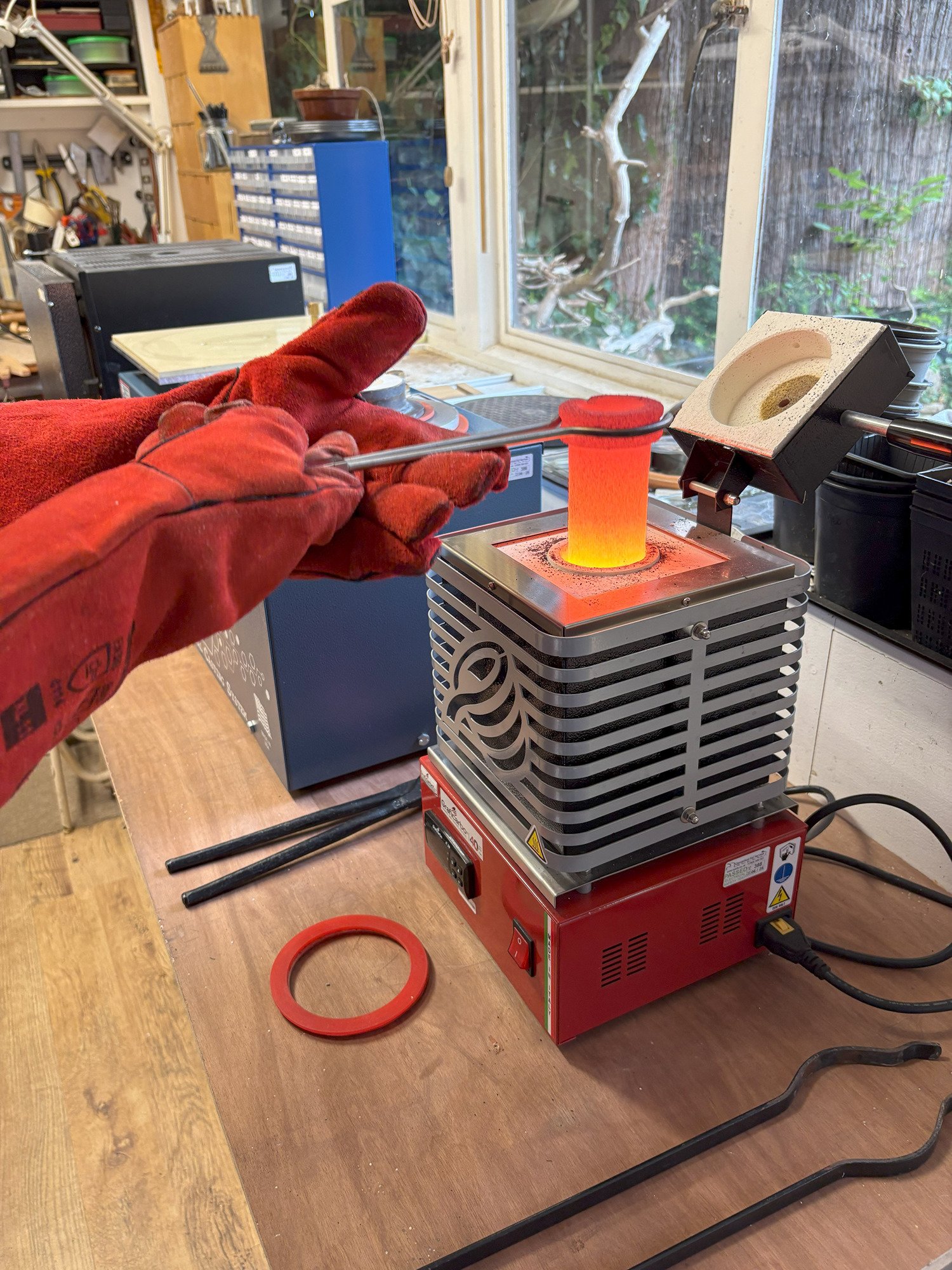

Once set, the flask is ready to go into the burn-out kiln to cure the investment and remove the wax. This process takes several hours under controlled temperatures to ensure that all the wax has been removed.

When the wax has burnt out the flask is taken out of the kiln and placed in a vacuum chamber. The flask is still at a high temperature so heat-resistant protective gear is required.

Once in the vacuum chamber the vacuum is applied and the molten silver is poured into the flask via the sprue area. The vacuum pulls the silver into the mould, ensuring a precision fill of the mould and resulting in a perfect copy of the wax patterns.

The flask is then allowed to cool a while before the investment is removed.

Finally, the cast is completed and the wax tree and the patterns have now been replaced with silver.

The silver cast is now ready to be cleaned and the tiny silver sculptures will undergo more processes before they are finished and ready to be worn as jewellery.